Pre-Filter Wraps

Pre-filter wraps are designed to extend the life of filter elements by trapping particles before reaching the media. They can be used with almost any filter. Search Pre-Filter WrapsRequest a Custom QuoteAbout Pre-Filter Wraps

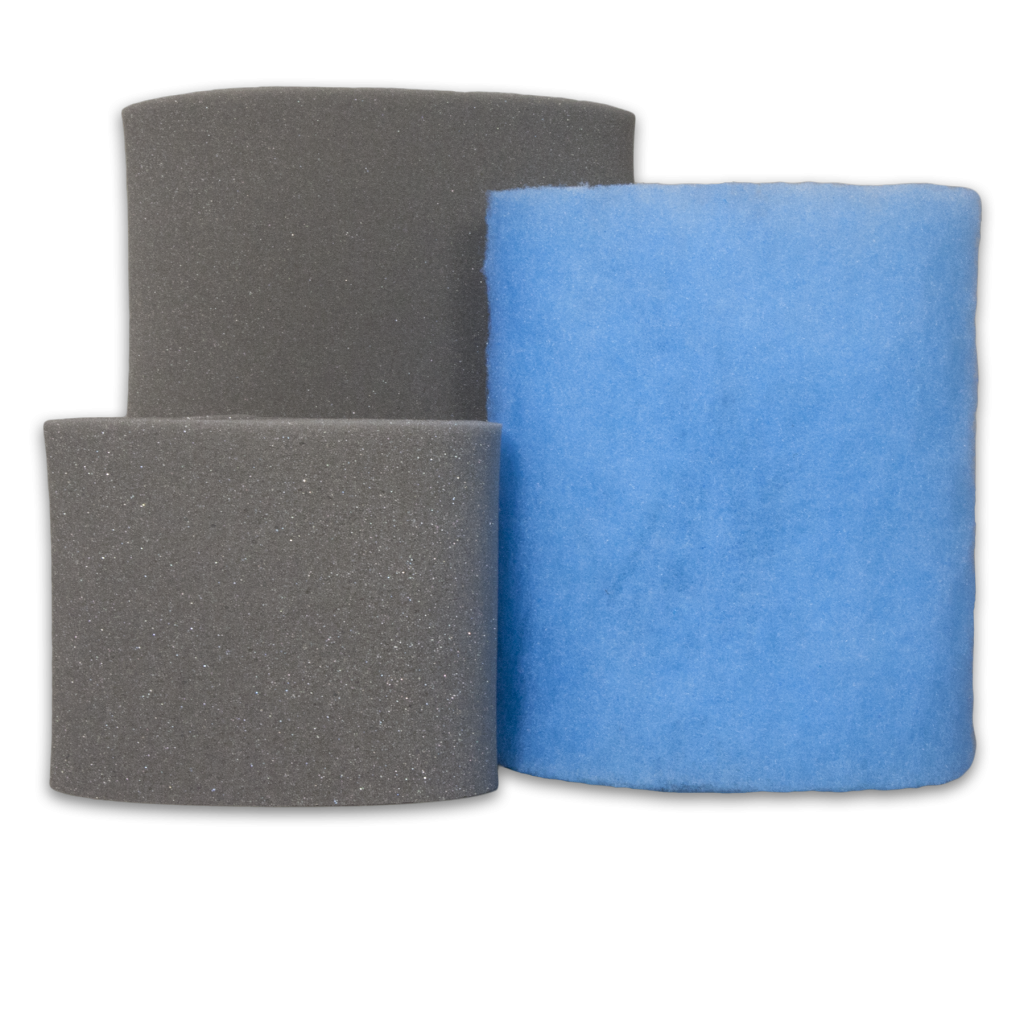

Replacement pre-filter wraps are designed to improve filtration and extend the service intervals of your industrial filter elements by trapping particles without much restriction of the air flow. They are manufactured from polyurethane foam or lofted Dacron®, and are easily slipped over the outside of a cartridge-style filter element. Most pre-filter wraps can be removed, cleaned, and reused.

Pre-filter wraps are also referred to as; jackets, pre-wraps, or filter wraps.

Commonly Crossed Brands

Applications

Pre-filter wraps can be found across industries and throughout numerous applications.

Pre-filter wraps extend the life of filter elements by trapping particulate, absorbing moisture, and preventing build-up or clogging of industrial filter elements.

They also remove dust and contaminants from air, gas, and liquid streams, and collect vaporized oil from industrial equipment.

Pre-filter wraps can be added to almost any filter.

Benefits

- Built to OEM or custom specifications.

- Designed for more efficient performance than OEM replacement pre-filter wraps.

- Compatible with your original equipment.

- Most pre-filter wraps are washable at the job site.

- Made in the USA, with high-quality, domestically sourced materials.

- Sidco pre-filter wraps will provide you with a significant saving in cost.

Specifications

- Media – Lofted dacron, polyester felt, polypropylene felt, reticulated foam, urethane foam

- Options – sewn seam or velcro attachments

- Unique Features – Some materials can withstand high temperatures, are flame retardant, or made from HEPA material. Most of our foam pre-filter wraps can be cleaned at the job site using just soap and water!