Custom Filters

Custom filters and custom filter design is a specialized service that Sidco has offered since the founding of our company. We use a collaborative process to reverse engineer a filter that will meet your needs and specifications. It entails evaluating your needs, as well as utilizing a variety of tactics; while developing a new manufacturing design or sourcing specialty raw materials. Sidco is one of the few manufacturers who will assist with a custom filter, unique application, or reverse engineer a filter. View Construction CapabilitiesGet a QuoteCapabilities & Opportunities

Sidco has a variety of capabilities to manufacture custom filters for your unique application. We can work with an OEM on a new application, customize an existing filter to better suit your needs, or reverse engineer an existing filter.

Our team is also happy to evaluate new designs, specifications, or custom filter projects that are not high-volume. One of our niche areas is specialized, low-volume applications or special modifications to current filters.

The construction of a filter can vary depending on the needs of its application. Sidco has various construction materials and capabilities to accommodate these needs. We work with each customer to create a custom filter design that fits their parameters.

These special constructions are developed for both our cylindrical filters, as well as our panel designs.

Construction Capabilities & Materials

Specialty materials include 304 and 316 stainless steel, reinforced support for high pressure or high-flow applications, custom sizes, unique designs, and many others.

Specialty options include:

- 304 stainless steel and 316 stainless steel

- Reinforced support for high pressure or high-flow applications

- Custom sizes

- Unique designs

- Flanges

- Gaskets

- Custom fabricated end caps

Molding Capabilities & Materials

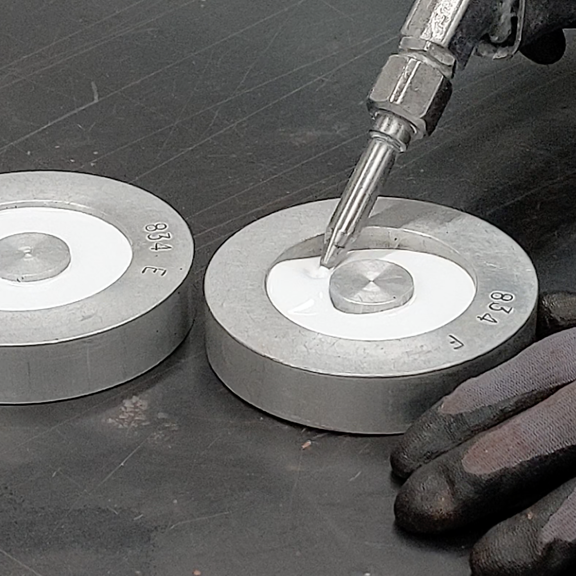

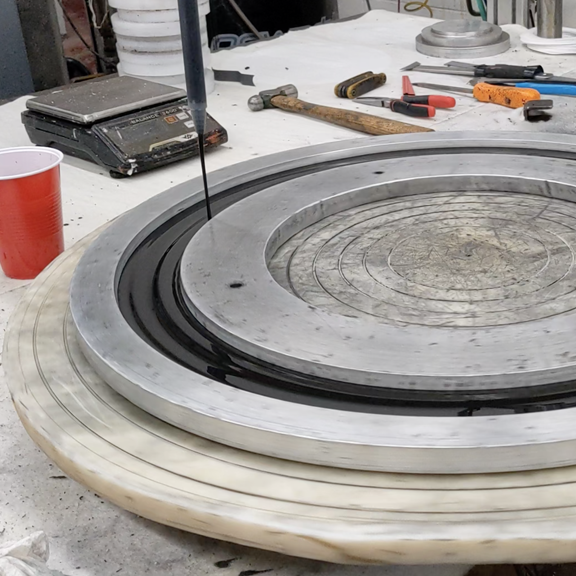

We can provide uniquely designed end seals with special seals, risers, flanges, other variations, and custom imprinted or stamped molds. Our molding capabilities extend beyond custom filters to unique applications that may need implementation of urethane mold.

Extensive Mold Library

- Over 900 existing in-house molds to choose from.

- Custom molds can be designed, cut, and stored at our on-site tooling shop.

Standard & Custom Seals

- 0.0625″ standard seals are evenly placed throughout the molded end cap, providing a reliable and consistent seal.

- Customize seal quantity, height, and width to meet your project’s specific requirements.

Custom Mold Sizing

- Inner diameters start as small as 0.3125″.

- Outer diameters up to 36.0″.

- Thicknesses range from 0.125″ to 0.375″ inches, ensuring the perfect fit for your application!

Custom Molding Capabilities

- Customize stamps and imprints to meet your unique needs.

- Threaded seals enable easy installation and secure system integration.

Molding Compounds

Sidco’s proprietary polyurethane is a rigid formula that has been designed to provide a strong cap with excellent sealing and a longer life than the urethane our competitors use.

We also have a variety of specialty potting and molding compounds available for high temperature or corrosive environments:

-

-

- Epoxy

- Silicone

- Urethane

- High-temperature options

-

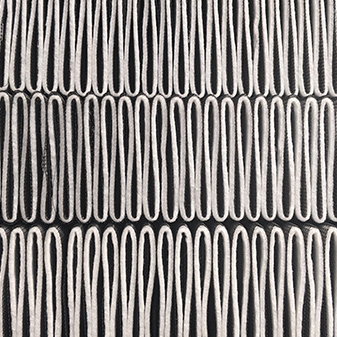

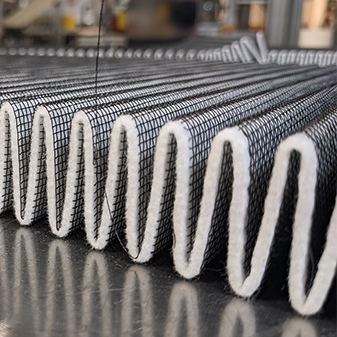

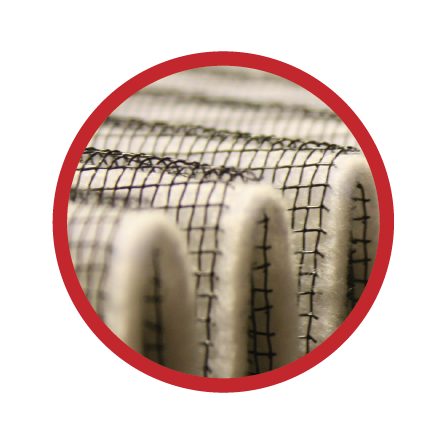

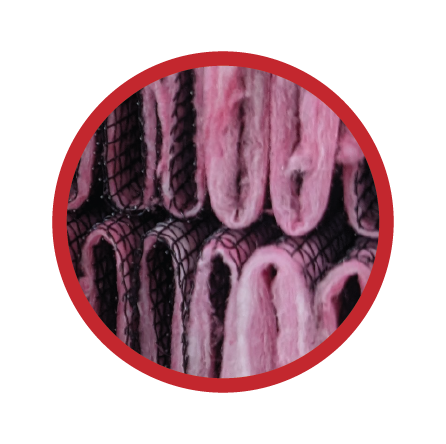

Pleating Capabilities

We use top-of-the-line pleating technology to design and build custom filters that meet your specifications. Much of our filter media can be layered, pleated, and adjusted to maximize surface area to optimize performance and efficiency ratings. Pleating also extends the life of the filter and equipment.

Customizable Pleat Dimensions

- Pleat widths up to 36.0″.

- Pleat depths from 0.25″ to 6.0″.

Multi-Layered Pleating

- Layer papers, felts, wovens, non-wovens, and metals to achieve your desired efficiency ratings.

- Up to 6 layers of material can be pleated together.

- Available in a customizable range of sizes, depths.

Mini Pleating

- Provides pleat support and consistent spacing to improve airflow.

- Range of 4-11 pleats per inch.

Glue Beads

- Prevents pleat pinching in HEPA, ULPA, and ASHRAE media.

- Provides even spacing and maintains structural integrity.

- Secures the optimal media area for air flow.

Pleat Lock

- Creates a self-supporting media structure.

- Promotes uniform fin spacing.

- Maintains media stability.

- Typically found in dust-collecting filters.

- Available in 1.875″ fin depth.

Specialty Media Options for Custom Filters

Many of our filters can be easily customized to use a variety of requested media. Available media include options rated for high temperatures, high performance, and special environments and range from 0.3 microns to 750 microns.

HEPA, ULPA, & ASHRAE

Capable of removing 99.97% of dust and allergens with a high efficiency. Sidco’s HEPA media is available in pleat depths ranging from to 0.0625″ to 6.0″.

Papers & Nonwovens

Standard cellulose paper, 80/20 high flow blend paper, 80/20 dust collector paper, reemay, nanofiber paper, spun bond, spun bond polyester, woven nylon, and flame retardant papers.

Felts

Polyester, fiberglass felt, aramid felt, rayon felt, rayon/nylon felt, polyester felt, polypropylene, polyester cotton blend, and dynaglass.

Coelescing Media

Fiberglass tube, pleated fiberglass, micro-glass, multi-layered coalescing media and other options.

Wovens

Standard cellulose paper, 80/20 high flow blend paper, 80/20 dust collector paper, reemay, nanofiber paper, spun bond, spun bond polyester, woven nylon, and flame retardant papers.

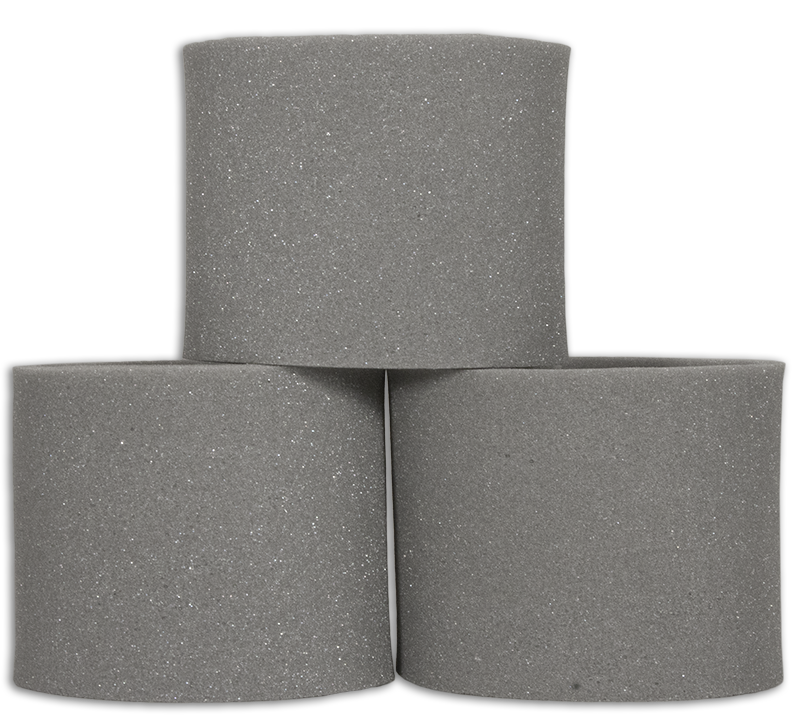

Foam

Urethane foam, reticulated foam, and lofted dacron.

Metals

Stainless steel woven mesh, epoxy coated screen, woven carbon steel, stainless steel screen, and more options available in various configurations and efficiencies.