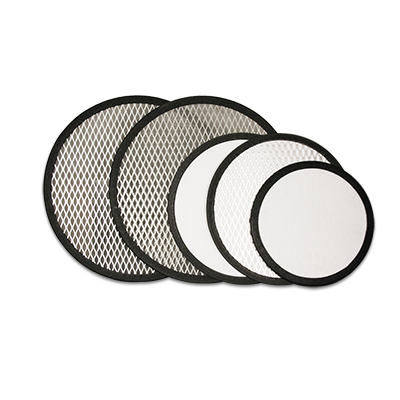

Disc Filters

Our disc filters are available in standard or custom sizes with various media options. Search Disc Filter ElementsRequest a Custom QuoteAbout Disc Filters

Disc filters are a flat, circular filter. They are constructed from stacked layers of circular-cut media, held together with a channel gasket around the circumference.

Disc filters are primarily used in pneumatic conveyor systems and cabinet filtration. Diluted, semi-dense, and dense phase pneumatic conveyors move bulk materials using low-velocity pressured air. Disc filters for pneumatic conveyors lower the velocity in tubes to minimize wear on equipment. A disc filter is inserted into a vacuum receiver on a pneumatic conveyor. Some equipment features a drawer unit for easier access to the filter element.

Disc filters are used for sorting material, cleaning air, and regulating air flow. Disc filters increase efficiency and prolong the life of your equipment. Sidco’s disc filters are built to fit original equipment manufacturer specifications and are designed to ensure structural integrity during handling, installation, and operation. Sidco offers disc filters in a wide range of sizes, with multiple options for medias and face screens.

Disc filters are also known as disk filters, flex filters, loader filters, or vacuum receiver screens.

Commonly Crossed Brands

Applications

Filtration for Pneumatic Conveyor Systems

Cabinet Filtration – Dust collection units in woodworking

Benefits

- All disc filters are designed to fit OEM specifications.

- Compatible with your original equipment.

- Designed to achieve equivalent or exceed OEM performance.

- Built with full media capacity.

- Washable media options available.

- Constructed from high-quality materials for durability.

Specifications

- Sizes – Made to OEM specifications with custom sizes from 4” to 36”.

- Media – Polyester felt, polyester felt with a Teflon® membrane, polypropylene felt, woven nylon, standard cellulose paper, stainless steel mesh, stainless steel screen, perforated stainless steel.

- Seal – Trimlock® channel gasket around the circumference.

- Support – Backed with expanded galvanized metal for support.

- Unique Features – Many of our disc filters can be cleaned at the job site. Cleaning your filter element is specific to the media type.