Mist Eliminators & Coalescing Filters

Our mist eliminating and coalescing filters are available in standard or custom sizes with various media options and configurations. Sidco’s coalescing and mist eliminating filters are a high-quality alternative to OEM replacements. Search Mist Eliminators & Coalescing FiltersRequest a Custom QuoteAbout Mist Eliminators and Coalescing Filters

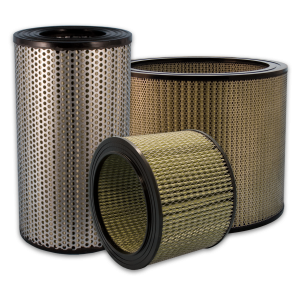

Mist Eliminator and Coalescing filters are a cylindrical-shaped cartridge filter, designed to improve filtration and extend the service intervals of your industrial filter elements by removing entrained liquid and oil mist from air or gas pipelines and vents. Coalescing and mist eliminator filters absorb oil mist, moisture, and vapor – separating liquid water and oil from compressed air using a coalescing effect. They also provide high-efficiency separation of oil mist and oil smoke from air or gas exhaust streams. Effective removal of visible oil, smoke, and mist from rotary and mechanical vacuum pump discharge air and extend the life of equipment and improve the work environment by trapping oil mist and particulate, absorbing moisture, and preventing contaminants from progressing downstream. They also reduce amounts of airborne pollutants, helping manufacturing companies comply with health and safety guidelines. Sidco Mist eliminator filters are a high quality alternative to OEM replacement filters.

Mist eliminator and coalescing filters are also referred to as; oil mist eliminators, mist eliminators, oil separators, coalescers, after filters, in-line coalescing filters, in-line coalescers, and separators.

Commonly Crossed Brands

Applications

Mist eliminators and coalescing filters are typically used in typically used in air and gas pipelines and vents. They use a two-stage process for separating liquid and oil from compressed air streams. They proceed to filter out solid particles, dust, and dirt from the air stream.

Coalescers are also used for separating different density immiscible liquids from each other such as; diesel, jet, and turbine fuel, insulating oil, and lube oil. The two-step process of a coalescing filter is extremely efficient because it provides a clean, impurity-free output. Coalescers provide high-efficiency separation of oil mist and oil smoke from air or gas exhaust streams, as well as effective removal of visible oil, smoke, and mist from rotary and mechanical vacuum pump discharge air.

Benefits

- Built to your specifications.

- Designed for more efficient performance than OEM mist eliminators and coalescing filters.

- Compatible with your original equipment.

- Made in the USA, with high-quality, domestically sourced materials.

- Constructed with heavy duty materials for durability.

- Premium grade components and oil-resistant polyurethane radial end seals are standard with this product line.

- Sidco mist eliminators and coalescing filters are a high quality alternative to OEM replacement filters.

Specifications

- Media – Polyester felt, polypropylene felt, spun bonded polyester, fiberglass tube, pleated fiberglass, epoxy coated steel screen, polypropylene felt, cellulose paper, HEPA media, lofted Dacron®, microglass, and more.

- End Caps – Oil-resistant polyurethane end seal, silicone, galvanized carbon steel, stainless steel

- Cores – Galvanized perforated carbon steel, flattened expanded galvanized carbon steel, perforated stainless steel, flattened expanded stainless steel

- Options – Reinforcing rings, lift lugs, gaskets, external or built-in pre-filter foam wraps, fin bars

- Unique Features – Some elements are available in HEPA grade media, with pre-filter foam wraps, or for high-temperature applications.