Manufacturing Spotlight: Custom Radial Fin Filter Elements

Your Specs. Our Expertise.

Tackle high-temperature applications, chemical compatibility challenges, and high-pressure environments with Custom Radial Fin Filters.

– Also known as Sewn End Filter Elements –

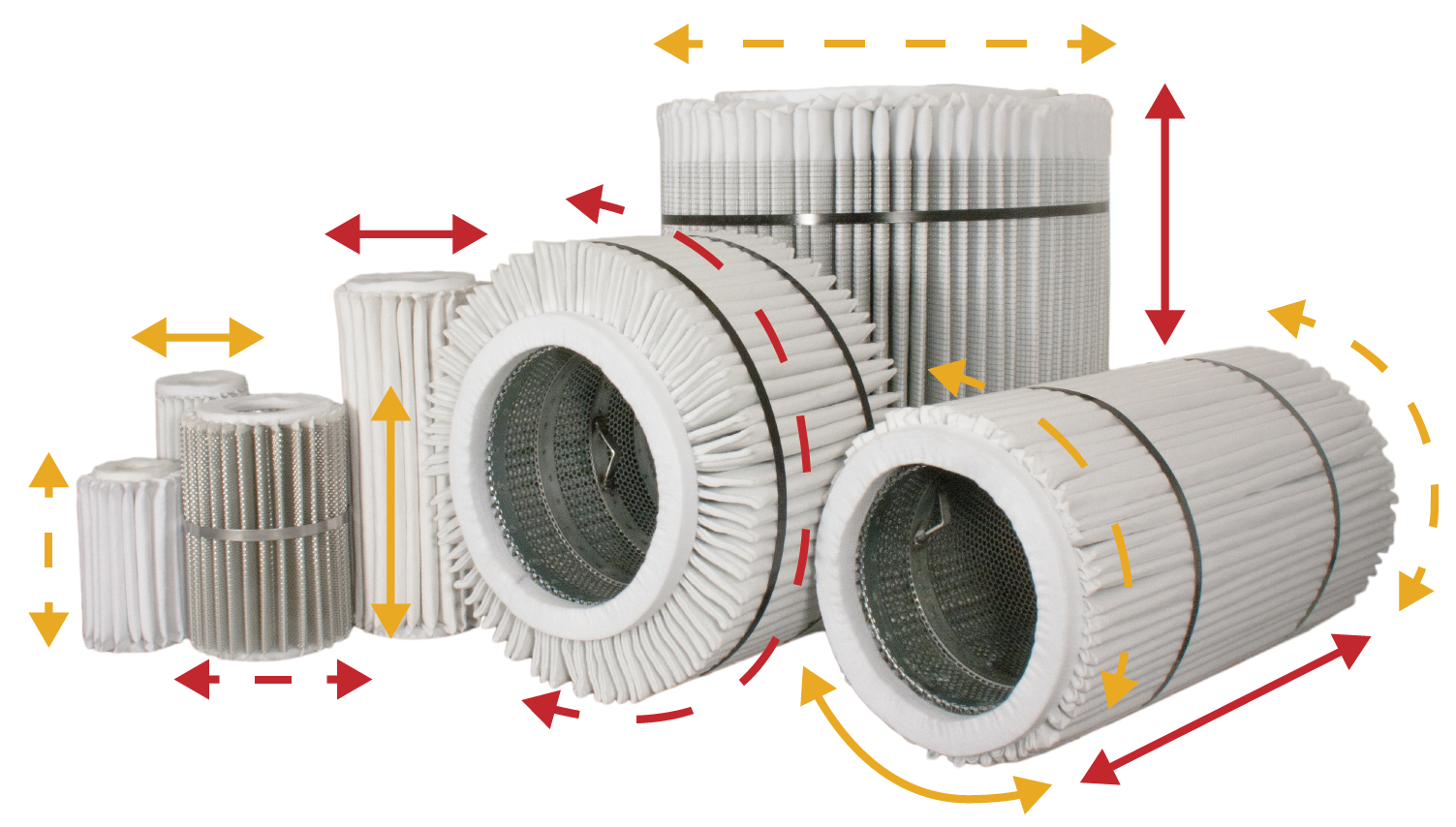

Custom Design Options

- Adjust ID, OD, and OH for a perfect fit, ensuring optimal filtration.

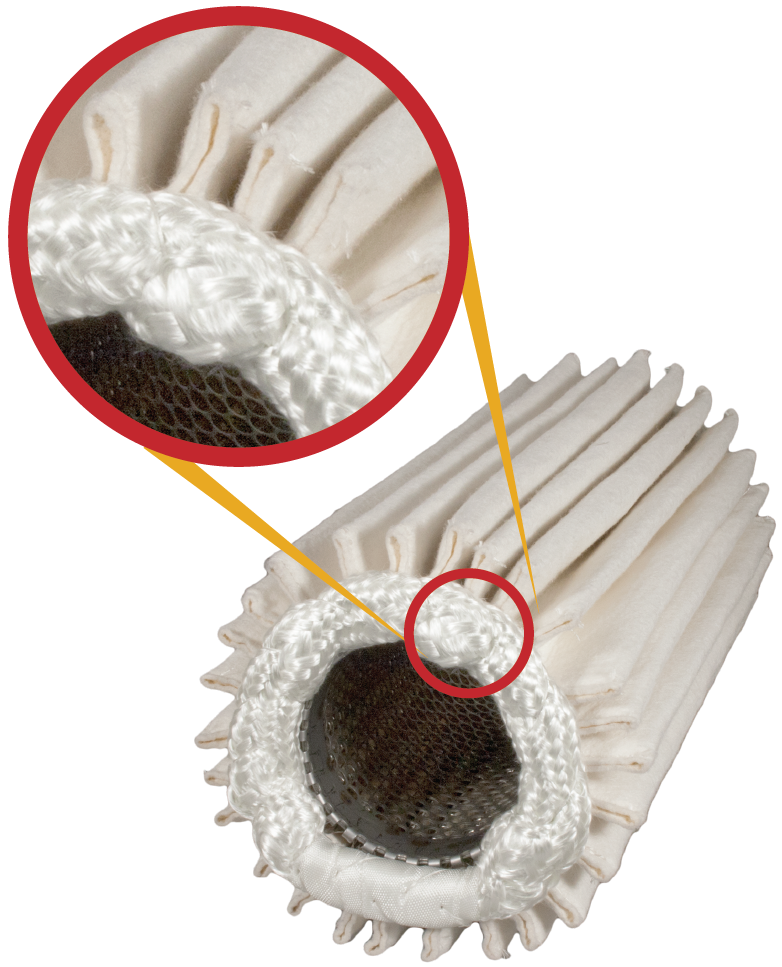

- Flanged Ends, also called Sure Seal Filters are more rugged and durable, making them ideal for stacking and sealing.

- Replace traditional gaskets with flanged ends enhancing durability and eliminating bypass.

High Pressure Environments

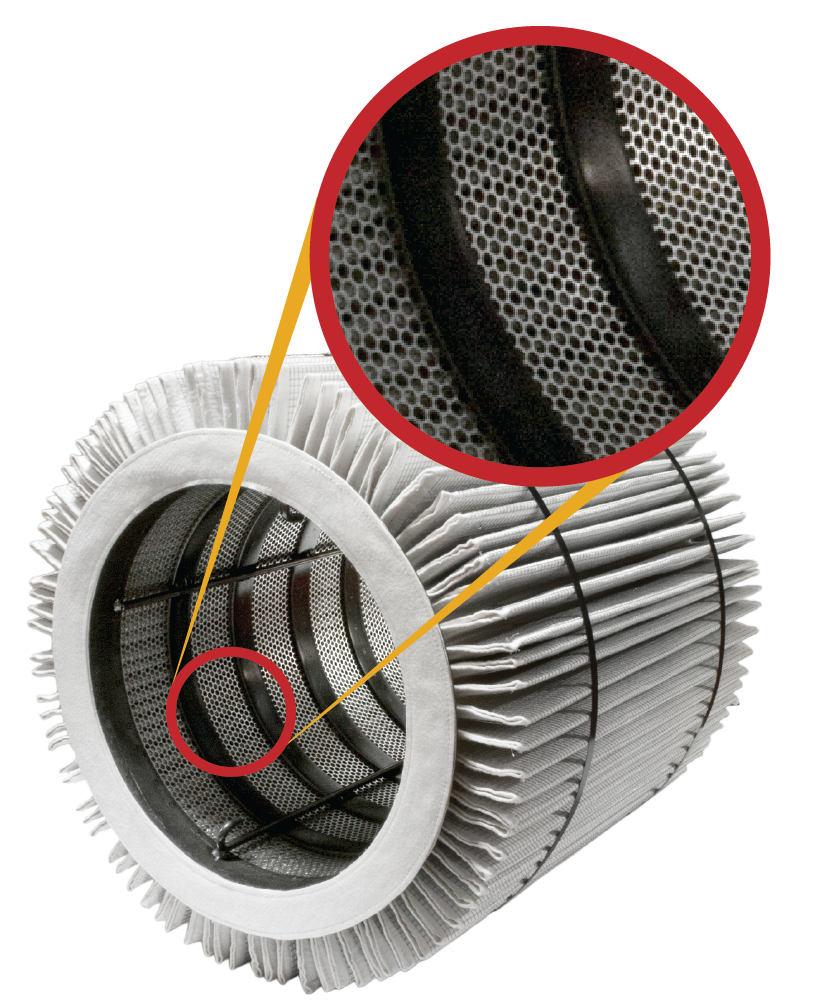

- Upgrade inner cores to low gauge carbon steel or stainless steel for durability in rugged applications.

- Add reinforced support rings for additional collapse protection.

- Add lift lugs or j-hooks to the interior for easier installation.

- Fin spacers can be placed inside each filter pleat pocket to enhance flow during high-pressure changes.

High Temp Applications

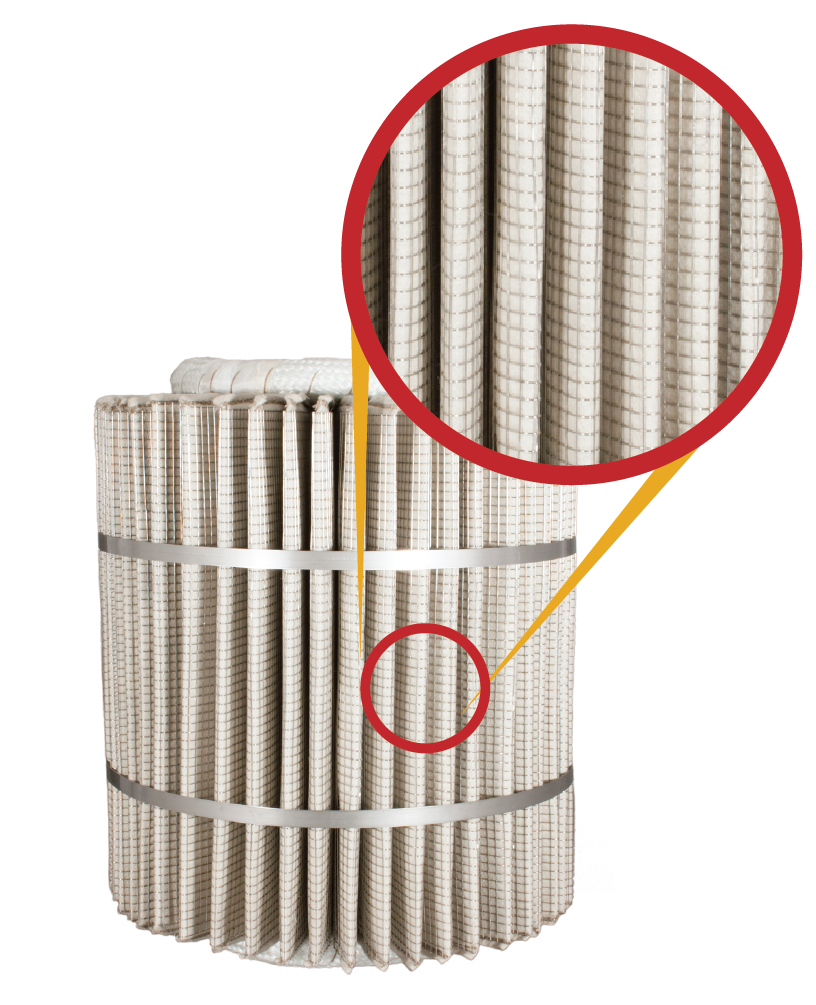

- High-temperature textile media up to 700˚F, with flame retardant choices.

- Customize gasket style, size, or material to withstand high temps.

- No adhesive or chemical compounds are used to ensure compatibility.

Chemical Compatibility

- Nomex, fiberglass, and other specialty media and materials ensure chemical compatibility.

- Upgrade metal components to 304 or 316 Stainless Steel to ensure optimal performance in highly corrosive environments.

- Specialty gasket material and application ensure effective sealing and reduced bypass.

Contact us to start your custom filter project today!

Our design and engineering team is happy to work with you on design, pricing, and application for your Custom Filter Design, Filter Manufacturing or Aftermarket Filter needs.

Read More Posts Like This One:

Watch Now: Custom Filter Manufacturing: Custom Radial Fin Filter Elements

We use advanced manufacturing techniques to design and build radial fin filter elements that meet your specifications. Radial fin filter elements are used in applications with high temperature and chemical compatibility issues because these filters can be made with no adhesive or chemical compounds… Watch Now!

Sidco Sales Tip: Close 27% More Sales

Derek Darling, President of Sidco Filter Company, talks about the easy tactic he uses to close 27% more sales…Watch Now!

Manufacturing to Serve OEMs

Our team can help you design, prototype, and manufacture HEPA, ULPA, and ASHRAE filters for your air cleaning applications…Read More