Manufacturing Spotlight: Molding Capabilities

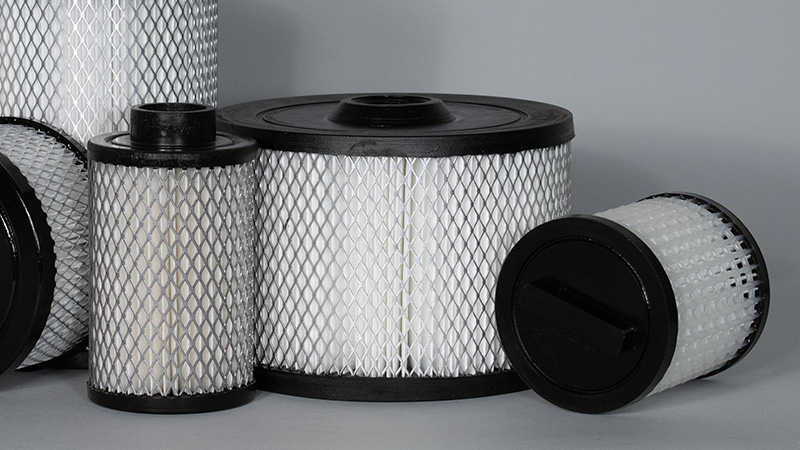

Molding Capabilities for Custom Filter Manufacturing.

Extensive Mold Library

- Over 900 existing in-house molds to choose from.

- Custom molds can be designed, cut, and stored at our on-site tooling shop.

Standard & Custom Seals

- 0.625″ standard seals are evenly placed throughout the molded end cap, providing a reliable and consistent seal.

- Customize seal quantity, height, and width to meet your project’s specific requirements.

Custom Mold Sizing

- Inner diameters start as small as 0.3125″.

- Outer diameters up to 36.0″.

- Thicknesses range from 0.125″ to 0.375″ inches, ensuring the perfect fit for your application.

Custom Molding Capabilities

- Customize stamps and imprints to meet your unique needs.

- Threaded seals enable easy installation and secure system integration.

Your Molding Material Options

Urethane

Rated up to 300˚F.

Polyurethane

Our proprietary polyurethane is a special-formula polyurethane that is more rigid than others.

PVC

A medium durometer, single-part epoxy used in food-grade applications.

Red Silicone

Ideal for oil applications, as it outperforms urethane.

White Silicone

Also ideal for oil applications, and ensures optimal performance and durability.

Epoxy Resin

A 2-part, hard-set epoxy used in stainless steel filters for high temperature and highly corrosive environments.

Contact us to get your project started!

Our design and engineering team is happy to work with you on design, pricing, and application for your custom filter needs.

Read More Posts Like This One:

Watch Now: Custom Filter Manufacturing: Pleating Capabilities

We use top-of-the-line pleating technology to design and build filters that meet your specifications. See what we can do for you in our video spotlight on Sidco Filter’s Pleating Capabilities!… Watch Now!

Sidco Sales Tip: Close 27% More Sales

Derek Darling, President of Sidco Filter Company, talks about the easy tactic he uses to close 27% more sales…Watch Now!

Manufacturing to Serve OEMs

Our team can help you design, prototype, and manufacture HEPA, ULPA, and ASHRAE filters for your air cleaning applications…Read More