Pleating Capabilities for Custom Filter Manufacturing

Pleating Capabilities for Custom Filter Manufacturing.

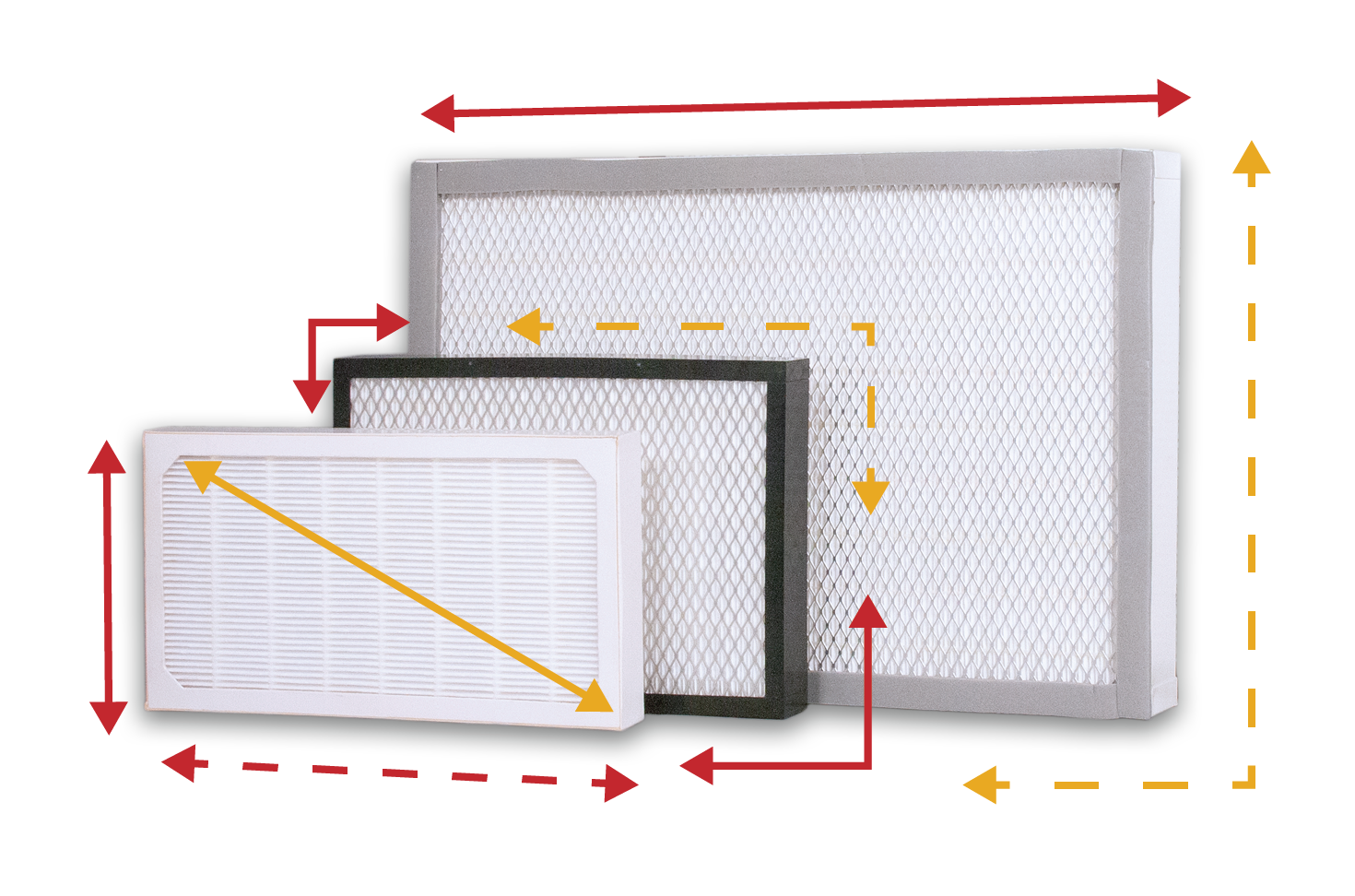

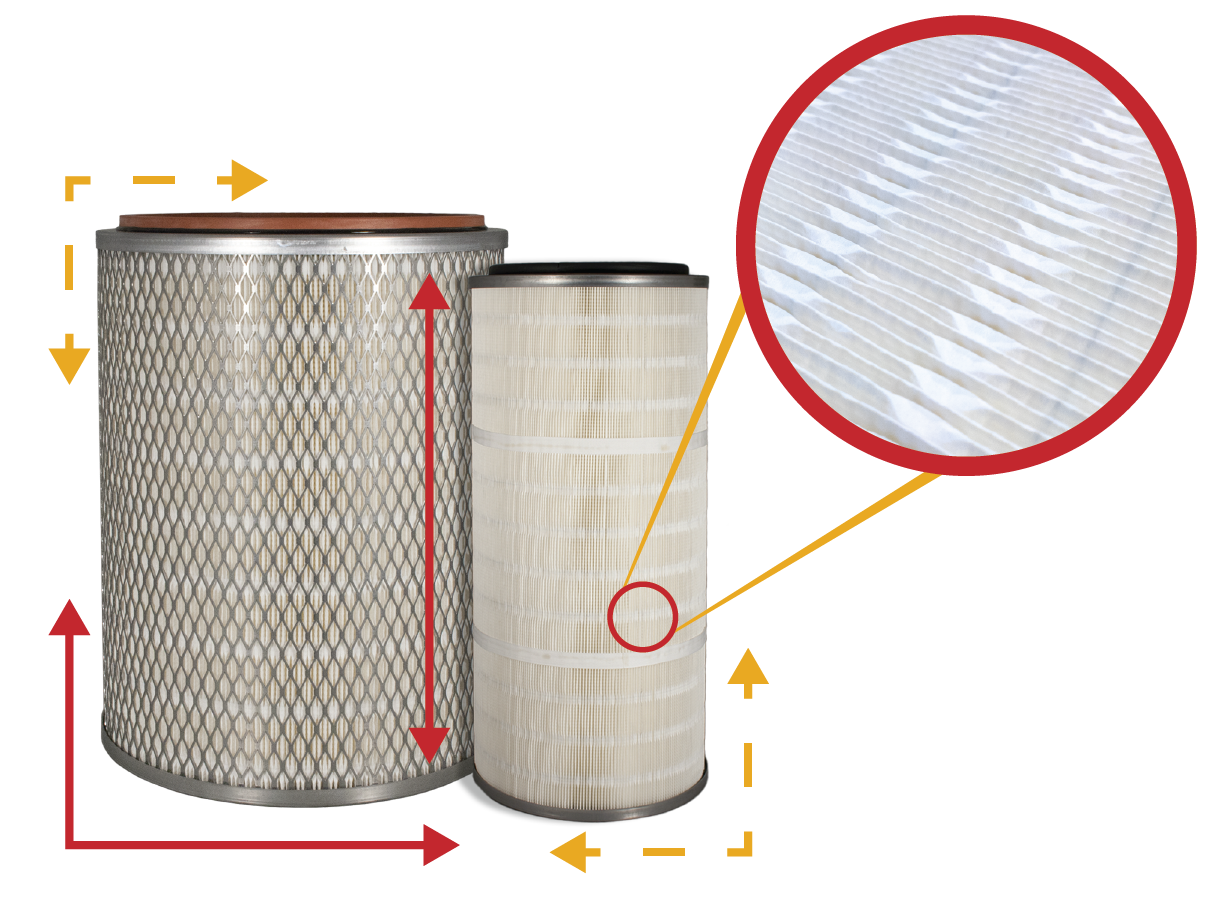

Customizable Pleat Dimensions

- Pleat widths up to 36.0″.

- Pleat depths from 0.25″ to 6.0″.

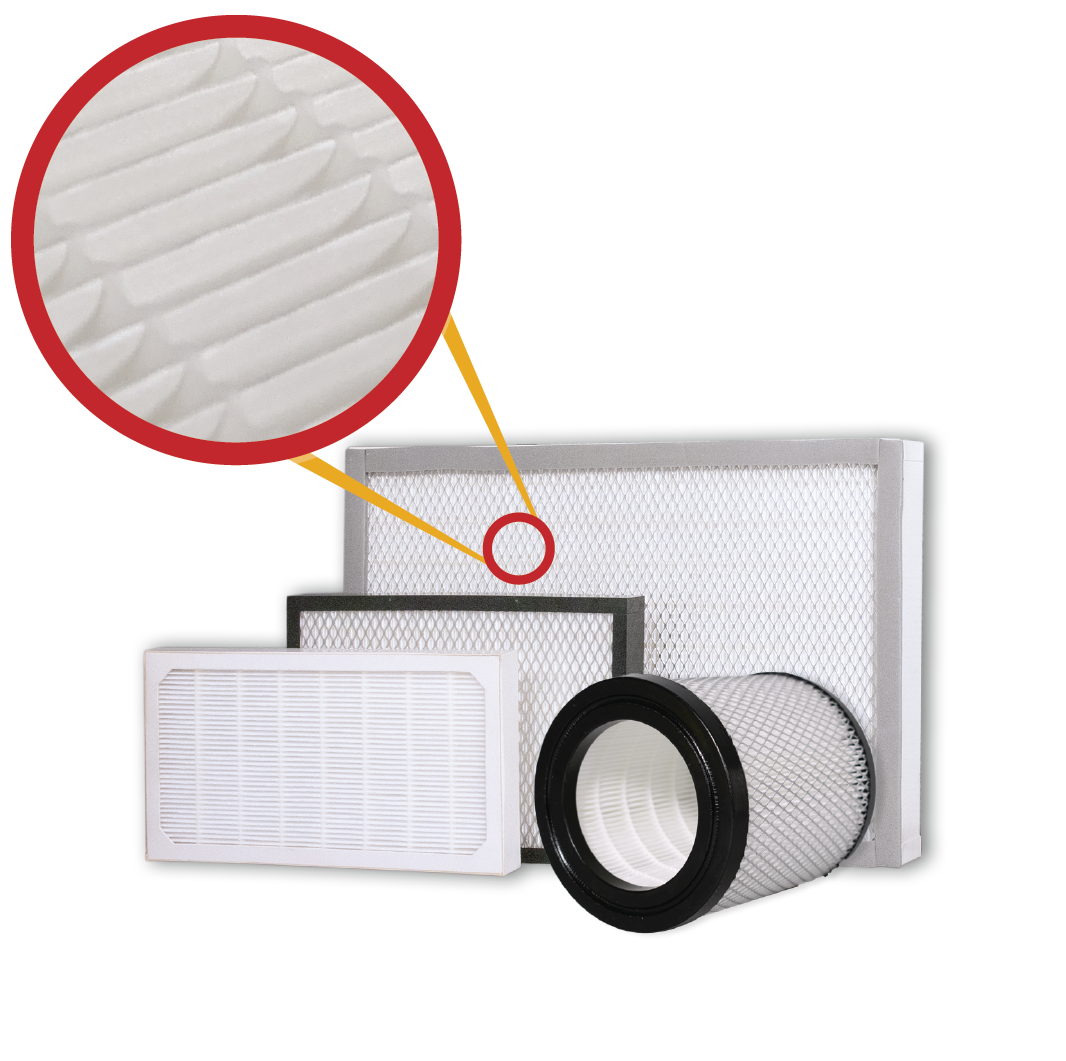

Mini-Pleating

- Provides pleat support and consistent spacing to improve airflow.

- Range of 4-11 pleats per inch.

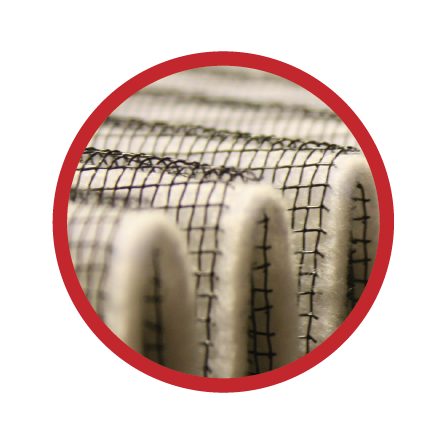

Multi-Layered Pleating

- Layer papers, felts, wovens, non-wovens, and metals to achieve your desired efficiency ratings.

- Up to 6 layers of material can be pleated together.

- Available in a customizable range of sizes, depths.

Glue Beads

- Prevents pleat pinching in HEPA, ULPA, and ASHRAEmedia.

- Provides even spacing and maintains structural integrity.

- Secures the optimal media area for air flow.

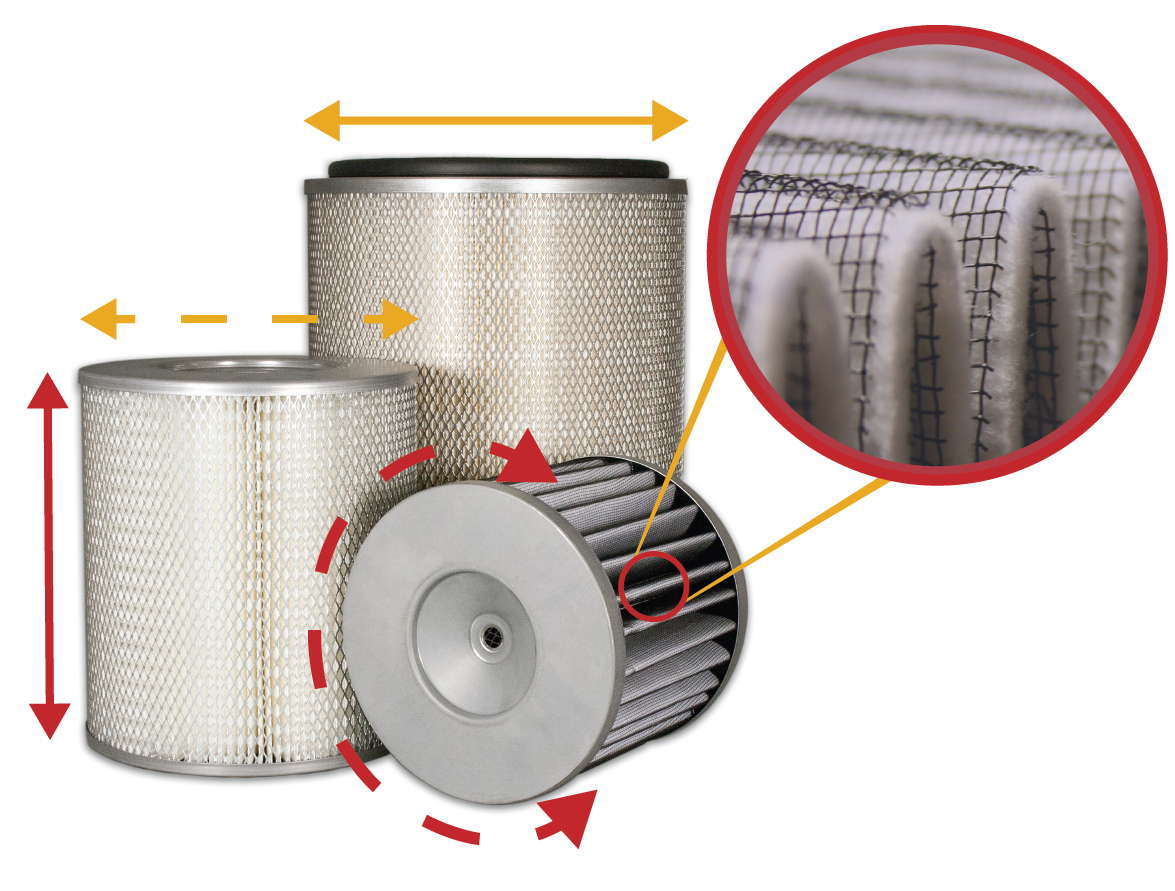

Pleat Lock

- Creates a self-supporting media structure.

- Promotes uniform fin spacing.

Maintains media stability. - Typically found in dust-collecting filters.

- Available in 1.875″ fin depth.

Materials We Can Pleat for You

Filters can be easily customized to use a variety of requested media.

Available media include options rated for high temperatures, high performance, special environments, and range from 0.3µ to 750µ.

HEPA, ULPA, & ASHRAE

Available with glue bead spacers and efficiencies from 0.3µ at 99.97% to 99.99997%.

Coalescing Media

Fiberglass, micro-glass, and more.

Wovens

Cotton, polypropylene, fiberglass, cotton terry cloth, teflon, and more.

Paper & Non-Wovens

Cellulose paper, 80/20 high flow blend paper, 80/20 dust collector paper, reemay, nanofiber paper, spun bond, spun bond polyester, and flame retardant papers.

Felts

Polyester, fiberglass, aramid, rayon, nylon, dynaglass, polypropylene, polyester cotton blend, and more.

Metals

Stainless steel woven mesh, epoxy coated screen, woven carbon steel, stainless steel screen, and more.

Contact us to get your project started!

Our design and engineering team is happy to work with you on design, pricing, and application for your custom filter needs.

Read More Posts Like This One:

Watch Now: Custom Filter Manufacturing: Pleating Capabilities

We use top-of-the-line pleating technology to design and build filters that meet your specifications. See what we can do for you in our video spotlight on Sidco Filter’s Pleating Capabilities!… Watch Now!

Sidco Sales Tip: Close 27% More Sales

Derek Darling, President of Sidco Filter Company, talks about the easy tactic he uses to close 27% more sales…Watch Now!

Manufacturing to Serve OEMs

Our team can help you design, prototype, and manufacture HEPA, ULPA, and ASHRAE filters for your air cleaning applications…Read More