3 Reasons to Do End of Year Filter Changeouts

Around the end of the year, many of our distributors work with companies that have extra budget monies to spend, and we advise that they use that cash on filter replacements. Stockpiling now while you have the budget is a great way to ensure that you will have enough replacement filters throughout the upcoming year. And, in truth, whether you have a budget surplus or not, we advise that any filter be replaced at the end of each year, similar to putting fresh batteries in smoke detectors during Daylight Savings twice a year. So, why is it important to change your filters?

Top 3 Reasons to Change Out Filters

1. Equipment Protection

A filter’s job is to protect equipment. Filters need to be changed to keep running effectively and efficiently and to prevent equipment failure. Conversely, if a filter hasn’t been running often, you still want to change it, because if you stop a system and restart it, also called a hard start, the filter media can become loaded or blinded off. Avoid unnecessary downtime by regularly changing your filters.

2. Energy Efficiency

Why pay a higher energy bill if you don’t have to? Clean filters are more energy-efficient, saving you important dollars.

3. Improved Air Quality

A new filter provides cleaner air in both the system and its surroundings, which is better for people, the environment, and the equipment itself.

Determine a Preventative Maintenance Schedule.

Now that you understand the importance of filter changeouts, you need a game plan – a Preventative Maintenance Schedule. This will keep you on track and your filters replaced on a regular basis, keeping equipment running smoothly. Preventative maintenance schedules should be set up around optimal time frames based on filter usage, running hours, and replacement needs. Keep in mind that filters will need to be changed more than just once at the end of the year.

There are two different ways to determine the need for a filter change: monitor the pressure, and perform a visual inspection.

1. Monitor the Pressure.

If you notice a drop in pressure, that often indicates that a filter is losing efficiency because of use and wear. It is likely time to change your filter.

2. Visual Inspection

Take a look at the filter. Does it have heavy loading of particulate? How about a change in color? Are there any holes in the media? Is there any moisture built up in the filter? Are there voids in the seal? Answering yes to any of these could mean it’s time to change your filter.

Filter replacement should be a key part of any maintenance plan and schedule. Regularly changing filters will keep your equipment protected, running efficiently, and will provide cleaner air. Be sure to monitor the filter pressure and do a visual inspection throughout the year to check for other times when filters should be changed. Don’t forget, now is a great time to use some of that end-of-year budget and stockpile some extra filters to use throughout the upcoming new year!

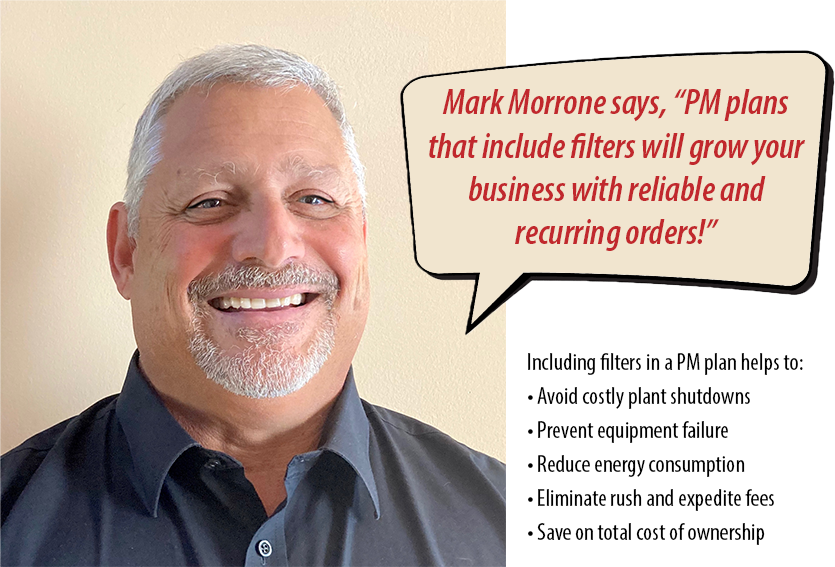

Mark Morrone, our Director of Sales and Business Development, is available to assist you with setting up recurring filter orders to keep your PM plans on schedule!

Read More Blog Posts Like This One:

How to Convert Customers from OEM to Aftermarket - Q&A with Andrea FitzGerald

Quite often, I hear “my customer is not happy with the quality of their filter”, “my customer would like to save on costs”, or “my customer is tired of waiting on long lead times”. An end-user shows the need or desire to move away from the OEM but is resistant for a variety of reasons.… Read More

Help Your Customers Find Filters in Their Facilities

To be a full-service filter sales professional, it is essential to be able to identify where filters may be located inside your customer’s facility or plant…Read More

5 Reasons to Have a Preventative Maintenance Plan

Help your customers increase productivity and reduce operating costs by developing and adhering to a Preventative Maintenance Plan that includes filters from Sidco…Read More